Don't miss our special offers - Contact Us Now!

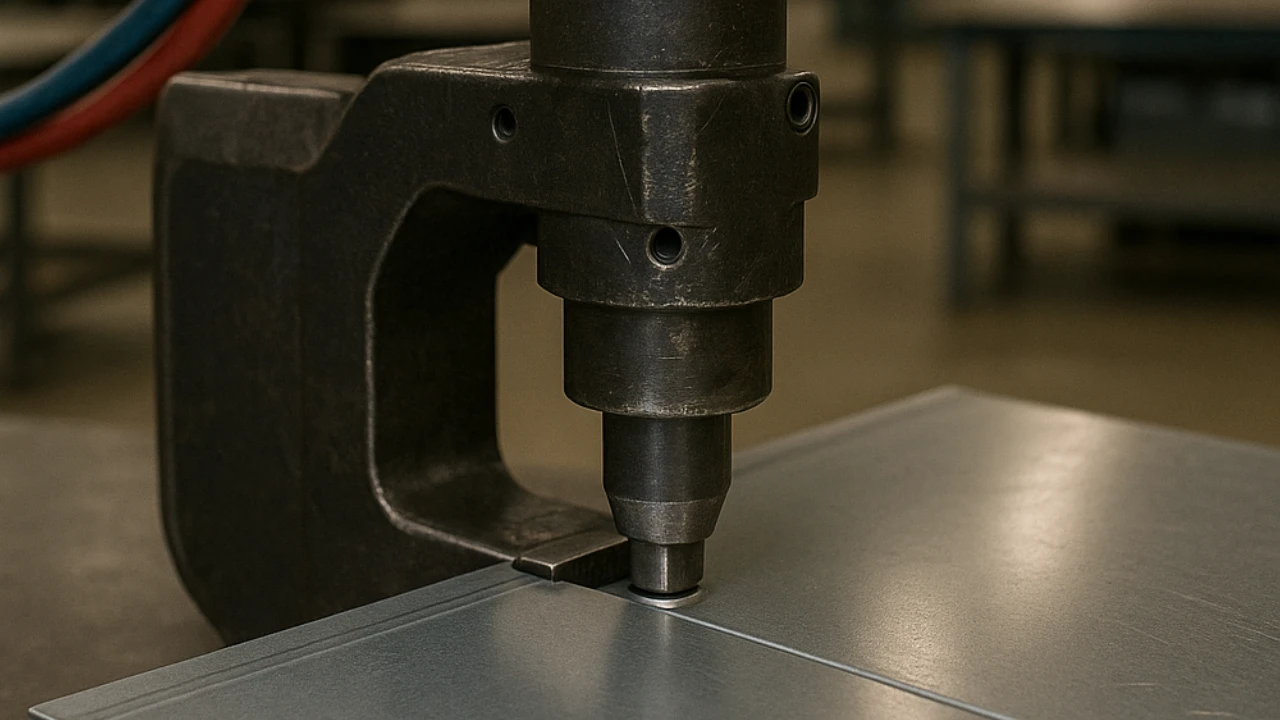

The Benefits of Pneumatic Tools in Industrial Sheet Metal Joining

Benefits of pneumatic tools are becoming increasingly evident in industrial settings where speed, reliability, and safety are critical. Powered by compressed air rather than electricity or hydraulics, pneumatic systems offer unique advantages for sheet metal joining operations—especially in high-volume, precision-driven environments.

From lighter tool weight to consistent force application, pneumatic tools are widely used in manufacturing sectors like HVAC, automotive, and appliance production. In this article, we’ll explore how these systems work, how they compare to other technologies, and why they’re a smart choice for many modern production lines.

You can learn more about our advanced clinching machines on the homepage or browse the full range of pneumatic clinching tools designed for industrial sheet metal applications.

What Are Pneumatic Tools?

Pneumatic tools are devices powered by compressed air, rather than electricity or hydraulics. In industrial environments, they are used to perform tasks such as clinching, pressing, fastening, cutting, and forming, offering high efficiency and precision with minimal electrical risk.

A pneumatic system typically consists of:

- An air compressor that generates and stores compressed air

- Hoses or tubing to deliver pressure to the tool

- A pneumatic actuator that converts air pressure into mechanical force

In sheet metal joining applications, pneumatic tools play a key role in cold forming operations, such as those performed by clinching machines, where they deliver consistent and repeatable pressure cycles without heat.

Because they are lighter than hydraulic systems and require less maintenance than electric tools, pneumatic systems are widely used in:

- Automated assembly lines

- HVAC manufacturing

- Electrical enclosures

- Metal cabinet fabrication

- Industrial panel building

The combination of simplicity, speed, and safety makes pneumatic tools a core choice for high-volume and precision-driven production processes.

Key Advantages of Pneumatic Tools

Pneumatic tools offer several practical and strategic advantages in industrial manufacturing—particularly in applications where reliability, repeatability, and safety are critical.

Their use in sheet metal joining, including clinching and cold-forming processes, is preferred in many cases over electric or hydraulic systems.

1. Lightweight and Ergonomic

Pneumatic tools are typically more compact and lighter than their hydraulic or electric counterparts. This makes them easier to handle for:

- Long shifts

- Repetitive operations

- Tight or vertical spaces

2. High Power-to-Weight Ratio

Despite being lightweight, pneumatic systems generate high clamping and pressing forces relative to their size. This makes them ideal for portable clinching machines and production lines where space efficiency matters.

3. Consistent and Repeatable Force Output

Compressed air ensures a uniform pressure cycle, critical for cold-forming applications where consistency determines joint quality. This translates into:

- Fewer defects

- Better joint strength

- Lower scrap rates

4. Safe in Humid, Explosive, or Dusty Environments

Unlike electric tools, pneumatic systems are inherently safer in moisture-prone or flammable atmospheres because they don’t produce sparks or heat.

This makes them suitable for:

- Chemical industries

- Foundries

- Environments regulated under ATEX or OSHA safety standards

A detailed comparison of safety in pneumatic vs. electric tools is available via the Occupational Safety and Health Administration (OSHA) official guidance.

5. Low Maintenance and Operating Cost

Pneumatic tools have fewer moving parts and no electronics, resulting in:

- Less downtime

- Easier servicing

- Long service life when properly lubricated and filtered

They also require no batteries, wiring, or electronic boards, making them more durable under heavy industrial use.

Pneumatic systems offer a clean, efficient, and scalable solution for many operations involving sheet metal joining. In the next section, we’ll compare them directly to electric and hydraulic systems to understand where each power source performs best.

Perfetto. Ecco la sezione completa “Pneumatic Tools vs Electric and Hydraulic Systems”, con tabella comparativa chiara, tono tecnico e focus su applicazioni industriali come il clinching.

Pneumatic Tools vs Electric and Hydraulic Systems

Choosing the right power source for sheet metal joining tools depends on several factors: force requirements, work environment, maintenance resources, and production speed.

Here’s how pneumatic tools compare to their electric and hydraulic counterparts in key industrial criteria:

Comparative Table

| Feature | Pneumatic Tools | Electric Tools | Hydraulic Tools |

|---|---|---|---|

| Power Source | Compressed air | Electricity | Pressurized hydraulic fluid |

| Force Output | Medium to high | Medium | Very high |

| Weight | Light | Medium | Heavy |

| Maintenance | Low (few moving parts) | Medium (electronics wear) | High (seals, oil, valves) |

| Start-Up Cost | Moderate (compressor required) | Low | High (pump, reservoir, lines) |

| Safety in Wet/Explosive Areas | High (no sparks) | Low (risk of shock/sparks) | Medium (fluid leaks possible) |

| Ease of Automation | High | High | Medium |

| Typical Applications | Clinching, cold joining, light pressing | Assembly, drilling, fastening | High-force stamping, deep-draw forming |

Summary:

- Pneumatic systems offer the best balance of force, safety, and cost-efficiency for sheet metal joining, especially in medium-duty repetitive tasks.

- Electric tools are useful for precision-controlled operations but may struggle in heavy industrial environments.

- Hydraulic systems are powerful but less portable, more complex, and require constant maintenance—ideal only when maximum force is required.

Use Cases in Sheet Metal Joining

Pneumatic tools are widely used in sheet metal joining processes where speed, repeatability, and clean deformation are essential. Their ability to deliver consistent force with minimal energy makes them ideal for cold joining methods, including clinching.

Here are key industrial contexts where pneumatic tools provide unmatched value:

1. HVAC System Fabrication

- Used for joining ducts, panels, and structural casings

- Allows clean, spark-free joining of galvanized or coated sheet metal

- Compatible with light-to-medium thicknesses (0.5–2.5 mm)

Example: The Python LA pneumatic system allows access to folded edges and complex profiles in HVAC components.

2. Electrical Cabinets and Enclosures

- Ideal for assembling control panels, distribution boxes, and metal covers

- Requires minimal surface damage—no sparks, no heat

- Suitable for powder-coated or pre-painted sheet metal

Example: Jurado’s pneumatic clinching tools offer a clean finish, preserving surface integrity and visual quality.

3. Appliance Manufacturing

- Used to assemble washing machine frames, oven casings, refrigerator panels

- Enables fast, reliable joining without compromising thermal insulation layers

- Lower operating noise and vibration—ideal for automated environments

4. Custom Metal Joining in OEM Production

- Supports flexible manufacturing with interchangeable tool kits

- Fast changeover between materials or joint types

- Easily integrated into robotic arms or semi-automatic workstations

Example: Jurado Tools’ machines come with custom round or trapezoidal tooling, compatible with various pneumatic configurations.

By using pneumatic tools in these scenarios, manufacturers benefit from:

- Faster cycle times

- Higher safety standards

- Cleaner joints with no need for rework

- Reduced operating costs

Why Manufacturers Choose Pneumatic Over Other Systems

When selecting joining technologies for sheet metal production, manufacturers consider not only the technical capability of a tool, but also its impact on workflow, costs, and long-term efficiency. Pneumatic systems consistently outperform other options in several of these categories.

Here’s why many production teams and plant engineers choose pneumatic tools:

1. Lower Long-Term Cost Per Cycle

While an initial air system setup (compressor + regulator) may require moderate investment, pneumatic tools:

- Have fewer wear components

- Consume no electricity during idle

- Require no consumables like gas, electrodes, or oils (in most cases)

The result is a lower cost per joint over time, especially in high-volume operations.

2. Easier Integration Into Automated Lines

Thanks to simple control logic (on/off via air pressure), pneumatic tools are:

- Easy to integrate with PLC systems

- Compatible with robotic arms and gantry automation

- Scalable for both manual and semi-automatic stations

They also support rapid actuation cycles, improving production output.

3. Safer and Easier to Operate

Pneumatic tools:

- Don’t generate sparks or excessive heat

- Eliminate risks of electrical shock

- Are often lighter and quieter, reducing operator fatigue

This simplifies training, enhances worker safety, and improves overall ergonomics on the shop floor.

4. Reduced Downtime and Maintenance

With fewer moving parts, pneumatic tools:

- Need minimal servicing

- Are less prone to failure in dusty or humid environments

- Allow faster troubleshooting and replacement

They are ideal for lean manufacturing setups, where downtime must be kept to an absolute minimum.

Pneumatic systems deliver a reliable, safe, and cost-efficient solution for many metalworking applications—especially where consistency, cycle speed, and clean joining are critical.

Explore Jurado Tools’ Pneumatic Clinching Systems

At Jurado Tools, we specialize in high-performance pneumatic clinching machines designed for sheet metal joining across HVAC, automotive, and industrial applications.

Our solutions combine:

- Integrated air pressure boosters

- Gyroscopic support systems

- Custom tooling kits for round and trapezoidal joints

- Compact C-frame structures for maximum accessibility

Whether you need a manual workstation tool or a system ready for automated integration, our pneumatic range ensures:

- Reliable force application

- Precise joint quality

- Minimal maintenance

- Adaptability to custom manufacturing needs

🔗 Browse our Pneumatic Tools

🔗 Learn more about our Clinching Machines

📩 Ask for Info — Get technical advice tailored to your production requirements.

🧠 Looking to upgrade your sheet metal joining process? Discover how pneumatic systems can improve speed, safety, and consistency—without compromise.